Our dance class wanted to have matching shirts for National Dance Day. So with a little research and ingenuity, we came up with this solution. Now we have an easy way to make custom silkscreens for any occasion.

Our dance class wanted to have matching shirts for National Dance Day. So with a little research and ingenuity, we came up with this solution. Now we have an easy way to make custom silkscreens for any occasion.

Art supply stores sell screen printing kits and materials, but they can be pretty expensive. We wanted to see if we could make our screen out of easy to obtain materials you may have lying around.

Finding the right fabric to use for this project was probably the most important step. We needed to find something that would have a tight even weave, but be very durable and reusable. Actual silk would be far too expensive, of course. We looked at the fabrics for a long time before settling on a sheer polyester curtain remnant (less than a yard) in a light blue. This gave us plenty of extra fabric for future projects or potential mistakes and only cost a few dollars.

For the embroidery hoop, we got a plastic 9 inch hoop. We had actually been looking for a larger wooden hoop, but this size turned out to be just right for this particular project. We bought 3 hoops so we could screen print more than one shirt at a time. This turned out to be a great decision as we were able to have a couple very successful shirt making parties.

We used two different ink brands: Speedball (opaque silver) and Yudu (black). They were both very thick. The Yudu is a computer screen printer that can be used in conjunction with the Cricut and many of their inks seem to be on sale right now. We found that the Speedball ink came through a bit cleaner and seemed to heat set a bit better. Regular fabric paint was messy and clumpy, but could be used in a pinch.

Our original plan was to use a squeegee to press the ink through the shirt. However, the screen printing squeegees seem expensive for such a specific use we decided to look for a more frugal solution. We found a brand new set of four silicon spatulas at the kitchen store for less than $5 that worked perfectly.

Total Time: 3-4 hours

Yield: 50+

Supplies:

Steps:

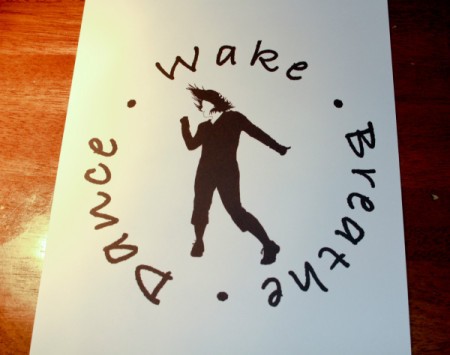

For this logo, we took a photo of our dance instructor, Lisa, during class. Then we outlined her and filled it with black to create a silhouette. After that, we added her tag line "Wake. Breathe. Dance." around the silhouette. Once the design was finalized (and approved by Lisa), we printed it on a regular 8.5x11 sheet of paper.

The Mod Podge will need to be applied in a thin coats, particularly the first one. After applying it to a small section, I found it helpful to flip the fabric over and look for any Modge Podge beads that needed smoothing on the back. Doing this helps create a smooth surface for when you are spreading ink and also fills in the holes in that area faster. You will need to apply 3-4 coats before all the white space is thoroughly filled in. If you make a mistake, fix it right away with a damp cloth or wet brush. Mod Podge is water soluble, but errors are much easier to fix while it is still damp.

Small errors can be fixed with a wet paintbrush or the entire shirt can be immediately washed before the ink dries, with varying success. We did flick excess paint in a spatter pattern on one particularly spotty print and it turned out great. Set the finished shirt aside for 30 minutes or until the ink is dried.

Add your voice! Click below to comment. ThriftyFun is powered by your wisdom!